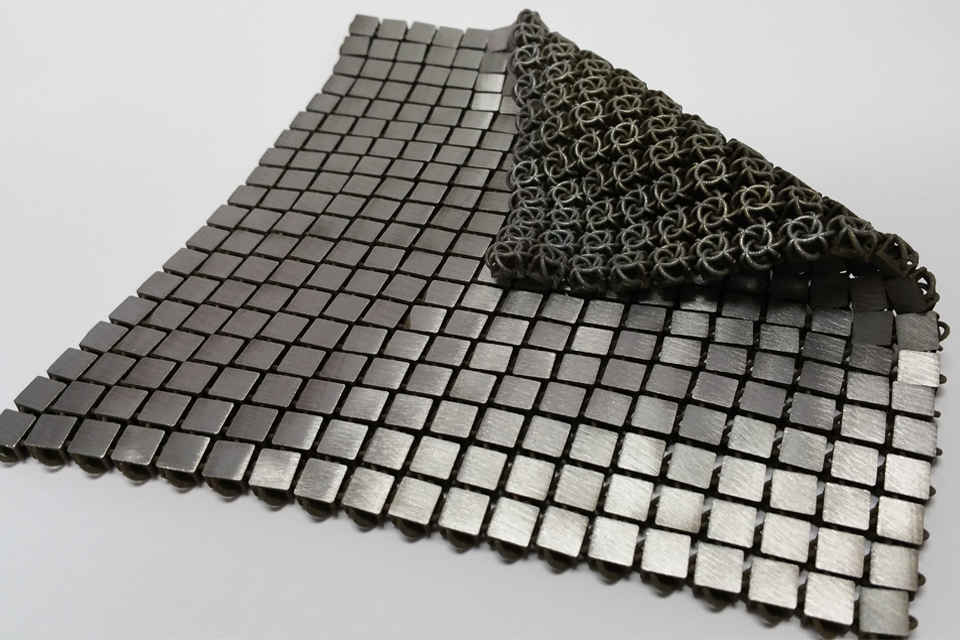

Talk about a trip. Scientists at NASA’s Jet Propulsion Laboratory (JPL) have used 3D printing technology to create a metal fabric that resembles a flexible, futuristic-like chain mail of sorts capable of being folded and shaped into all sorts of wild, innovative creations.

The strong silver fabric was printed as a single piece of metal and has four main functional properties— reflectivity, foldability, passive heat management, and tensile strength—that all have the potential to be multiplied and transformed many times over.

“We call it 4D printing because we can print both the geometry and the function of these materials,” said NASA Systems Engineer Raul Polit-Casillas. “If 20th-century manufacturing was driven by mass production, then this is the mass production of functions.”

Indeed it is, as the 3D-printed metal fabric has a myriad of different uses and functions. It could be used for an astronaut’s space suit, a shield to protect spacecrafts from meteorites, a way to manage temperature control (one side of the fabric reflects light while the other absorbs it), and it can even be folded into a compact package for expandable devices deployed from space, like antennas and other often large devices that assist with space and space travel.

What’s more, the material’s strength allows for it to be pulled and manipulated into various shapes, with no limit to size. For example, it could be used as an insulating “skin” of sorts for a trip to an icy planet or moon, like Jupiter’s Europa, and/or be folded over icy terrain, thereby preventing the ice from melting. And the best part? This is all just the beginning.

Polit-Casillas, the co-founder of JPL’s Atelier Rapid Prototyping Workshop, says that 3D printing creates all sorts of possibilities for metal fabrics and functions. “I can program new functions into the material I’m printing,” says Polit-Casillas. “That also reduces the amount of time spent on integration and testing. You can print, test, and destroy material as many times as you want.” He went on to explain that in the future, such materials could even be 3D printed in space, then recycled as many times as needed simply by breaking them down and reusing them.

Andrew Shapiro-Scharlotta and his JPL office help fund research for early-stage space technologies, and according to him, adding multiple functions to material at different stages of development can not only make building spacecrafts easier and less expensive, but also enable the creation of devices and fabrics that may have never been possible before, let alone heard of to begin with.

“We’re just scratching the surface of what’s possible,” says Shapiro-Scharlotta. “The use of organic and non-linear shapes at no additional costs to fabrication will lead to more efficient mechanical designs.”

And while the mechanical design aspects for space and space travel are truly exciting, imagine what this could mean for the world of fashion! Wearable metal fabrics that can morph and shape into different sizes and functions could have all sorts of wild and innovative practical uses for everyday living, let alone what it can do for creating never-before-seen looks and styles. Rather than simply recycling trends from past decades with small tweaks and changes, we could create entirely fresh ones that have never been seen or felt before—talk about a fashion statement!

“Depending on the weight of it, this would serve as a great option for so many elements in fashion,” says famed fashion designer Malan Breton. “I could see doing evening wear for women in this, it’s so malleable. I would also create a line of outerwear for winter in it—with its capability to absorb heat and detract moisture, it’s perfect for the athletes of winter and sub-zero temperatures.”

Yes, perfect for winter sports and escapes and plenty of other seasons and industries. Now the only question is, which designer will be brave enough to start using it? And which consumer will be brave enough to wear it.